So far, October was a better month for taking pictures, and it is time for the mid-October progress report! I may have taken too many pictures. I still find myself just starting on projects without taking before pictures. One day, I’ll remember to do this. October was a busier month, so this may be a very long post.

I am grateful for the work whenever it comes, but sometimes the busy work keeps me from doing things like website updates and other behind-the-scenes things that no one notices unless they break. Fortunately, that is not the case this month.

Product Sharing

Sometimes I get stuck in the everyday routine and forget to recognize when things make a difference in the project completion process. I do want to highlight the most recent product purchased, which I am grateful that I made the splurge on.

I have constantly struggled with hand-sewing needles because I always manage to bend them very quickly. I am not entirely sure why, but it does not matter what brand or type. By the time I get all the way around a single leg on a pair of pants hems, that needle is ever so slightly bent. When I am doing hand-sewn, no-cut hems on floor-length choir dresses, it is very noticeable. It is very frustrating because the needles basically become one-time use.

The picture is a screenshot of the product in the Walmart iPhone app.

I found these Singer needles at Walmart of all places. They were not super expensive, but they were not the cheapest option. Unfortunately (or fortunately), that day, they did not have a lot of selection for apparel sewing needles. They had a handful of packages left of these Singer-branded needles.

The ones I actually purchased were the “Singer Assorted Hand Needles,” but the packaging style is the same. These are the only needles that I have not bent on the first use. In fact, I am only on my second needle out of the package. For $2.37, these are amazing! I will buy again. I will have to try the quilting needle varieties to see if they are also an excellent choice.

The package is way easier to use than the spinning round dispenser thing. Each slot on the packaging opens independently so the needles do not get stuck as you turn the dial. There is even a compartment on the back of the case that holds a needle threader. I like to stick my “stick on thimbles” on the inside of this compartment so I always have one if I need one.

My only complaint about these needles is that the eyes are very small on some of them. I mean, very small! The needle threader is very helpful for these aging eyes.

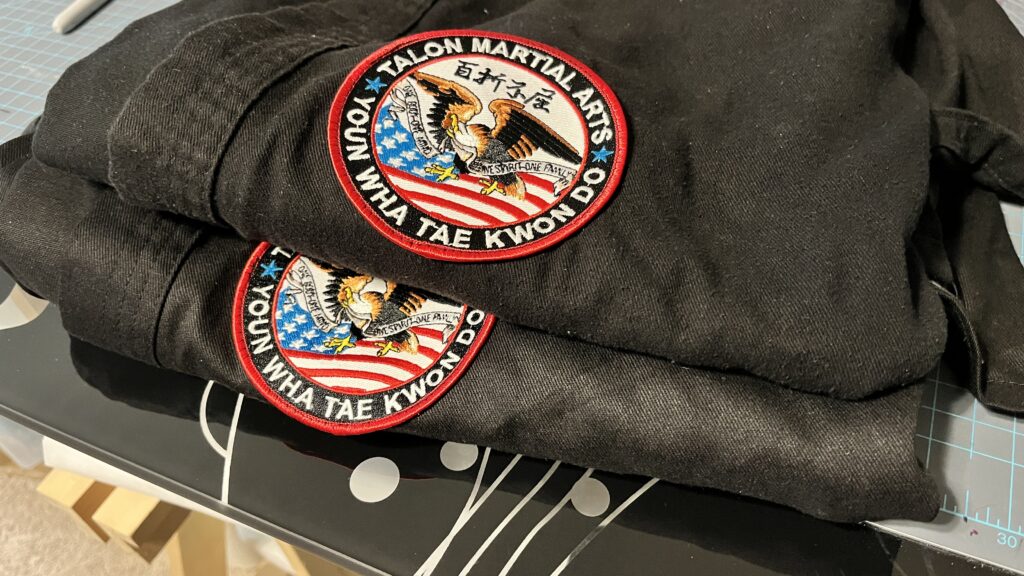

Sewing on Patches – Karate School

This month, was more patches from the local karate schools. It is regular business for me and I try not to complain too much about it. Many seamstresses hate sewing on patches, but I rather enjoy it. It is not difficult work, and after you have done a few hundred patches, it becomes quick work.

Templates make it quick to pin the patches into place and this makes it a lot faster to complete at the sewing machine. I resisted pinning for a long time, but precision became more important when the school started adding the embroidery onto the uniforms. The patch and the embroidery need to line up across the chest to make me happy with the job.

I was asked how I pin the patches without bending the pins. The answer to that question is, “I go through a lot of pins!” I do bend the pins, and I have come to accept this as a part of doing business. Some patches are easier to pin on because they are not very thick. For example, the patches with the yellow outer ring are easy to pin through the yellow part, but the patches with the black outer ring have thicker stitching and are much harder to pin through.

The reality is, I bend a lot of pins which reminds me, I need to refill my magnetic pin tray with another box of pins before the next round of testing brings me larger batches of uniforms.

Patches – Hook and Loop Fasteners

Most of the uniforms that I complete for the local karate school are sewn directly onto the uniforms. The average student will have 2-4 patches on their uniform at any given time.

In this case, I am replacing a lost patch. One of the younger instructors misplaced her school patch and needed a replacement. I put the loop part on the uniform, so I only needed to replace the patch with the hook part of the fastener.

However, some of the instructors teach at different school locations and have requested that the patches be “swappable” so they can utilize the same uniform and swap the patches as they need to based on where they are teaching.

These patches still need to be securely fastened onto the uniform so they do not accidentally come off and cannot be easily removed by an opponent while sparring.

Unfortunately, my machine is suffering from tension problems and needs to be serviced, but the instructors are so happy to have swappable patches, and they pay little attention to the rough coloring on the edges of the patches.

If there is anything seamstresses hate sewing more than patches, it is hook and loop fasteners! It certainly is not my favorite thing to do. While the loop part is not too bad, the hook part frequently causes problems, including tension problems and frequent broken threads. Someone advised me to sew with the hooks up, and it would not be a problem. That is not always the case.

Jeans Repair – Button Replacement

I have said it before, but not every job at Stacey Sansom Designs is glamorous. Small jobs are 100% accepted.

I keep a variety of jeans buttons in stock at Stacey Sansom Designs so these fixes can be done and returned very quickly. Unfortunately, reusing riveted buttons like those found on most jeans is not possible. New ones must be installed. Sometimes, the hole must be reinforced before a new button can be installed.

Patches – Logo Cover Up

I sometimes get patch sewing jobs where the customer wants to cover up a logo or other branding on garments with a new patch. This was the case this month for one client. They wanted to continue to use the jacket (it is a nice jacket), but they did not want to advertise a now-defunct company.

In this case, the patchy they wanted to use was a near perfect size to cover the logo in question. The patch already had hook tape on the back. I needed to apply the loop tape to the jacket.

I charge for each piece of the hook and loop fastener tape. If you only need hooks, you only pay for hooks. If you only need loops, you only pay for loops.

The logo the customer wanted to hide, was slightly larger than the patch itself, but they wanted to make sure the logo was hidden. In this case, the hoop tape was just cut a little larger. It was carefully aligned and pinned into place before sewing. The jacket is made out of a microfiber material. This can cause shifting while sewing; secure pinning yields the best results.

This is another one of those “not flashy” jobs, but these types of jobs mean the world to the client requesting it, especially if they already have the patches. Finding a seamstress willing to do the job is a hurdle. I offer these tasks because they do make a difference in the world for someone.

In this case, a perfectly good jacket can continue to be used as intended.

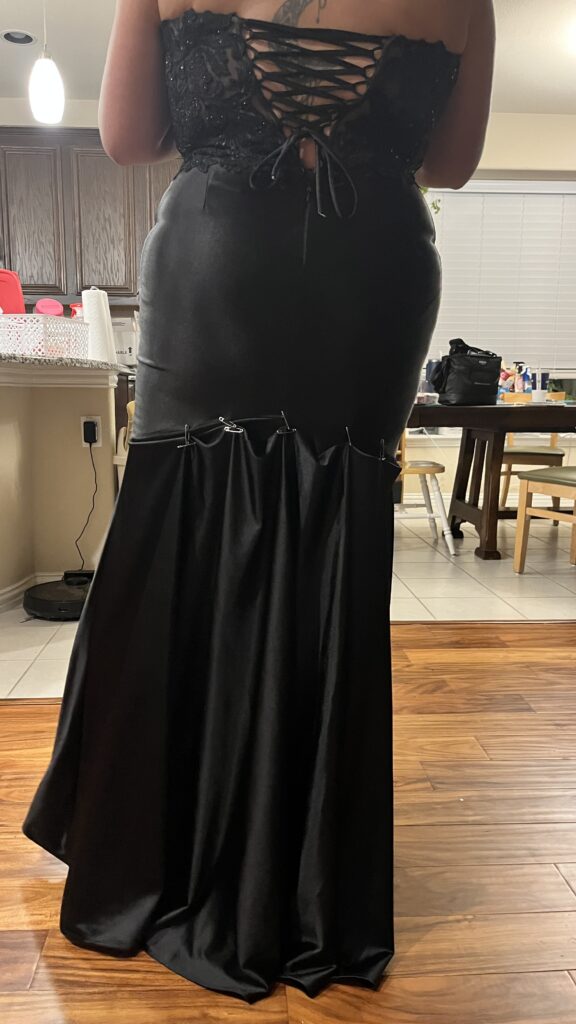

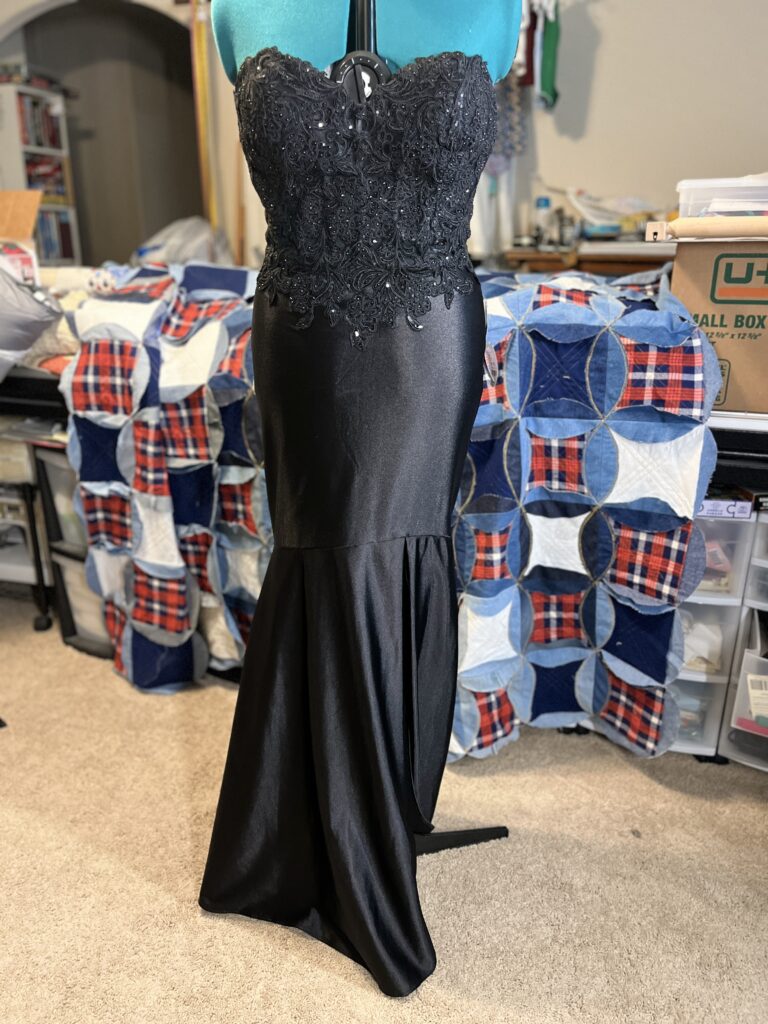

Dress hem and removing the train

When it is gala season, I get a few more dresses with special hem requests. Frequently, they are searching for someone to make the dress long enough to sweep the floor, but short enough to prevent tripping and falling. Trains are popular on formal dresses, but they are not always comfortable for everyone to walk and dance in.

At the fitting, she was not certain she wanted to remove the train, but she knew she did not want to trip over it. This is 100% understandable, especially if you have paid a lot of money for a dress. However, sometimes removing the train alters the overall look of the dress.

Like on wedding dresses, trains can be “bustled” as a way to get them out of the way. Initially, we pinned up for a 5-point bustle to evenly distribute the fullness of the train and shorten it so it would not be stepped on while wearing, walking, or dancing. The customer decided that she did not like the bulk of the bustle while moving and sitting, so it was marked for removal.

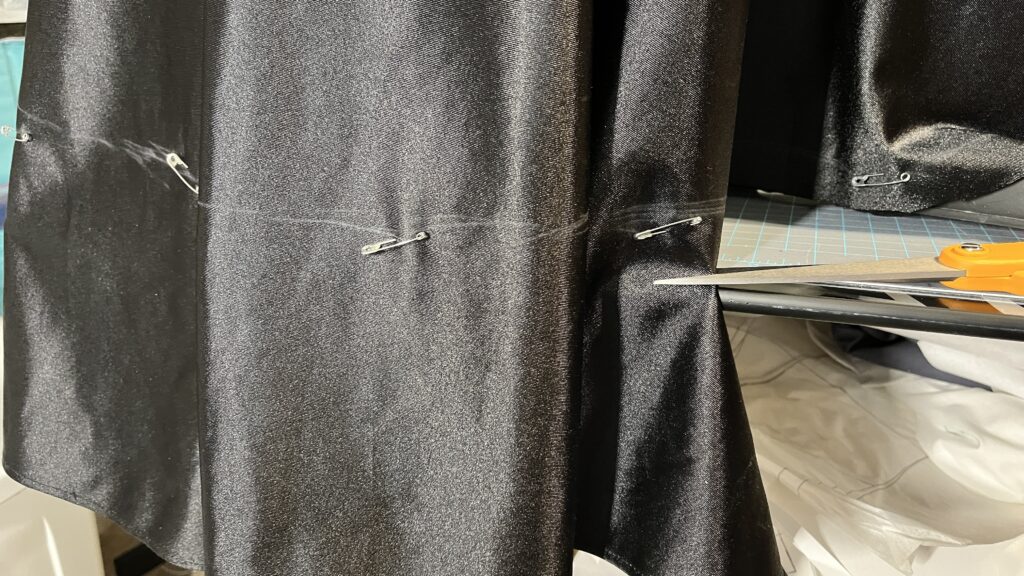

The original hemline is inspected to make note of current construction. In this case, I am not reducing the front length. It is where the customer wanted it. However, it quickly goes into the train, and she wants this removed. This requires me to unpick enough of the original hem at the transition points so the new hemline will smoothly transition from the original hem to the new hem without being noticeable. The amount of hem being picked out varies, but it is usually 2-3 inches on either side of the transition point.

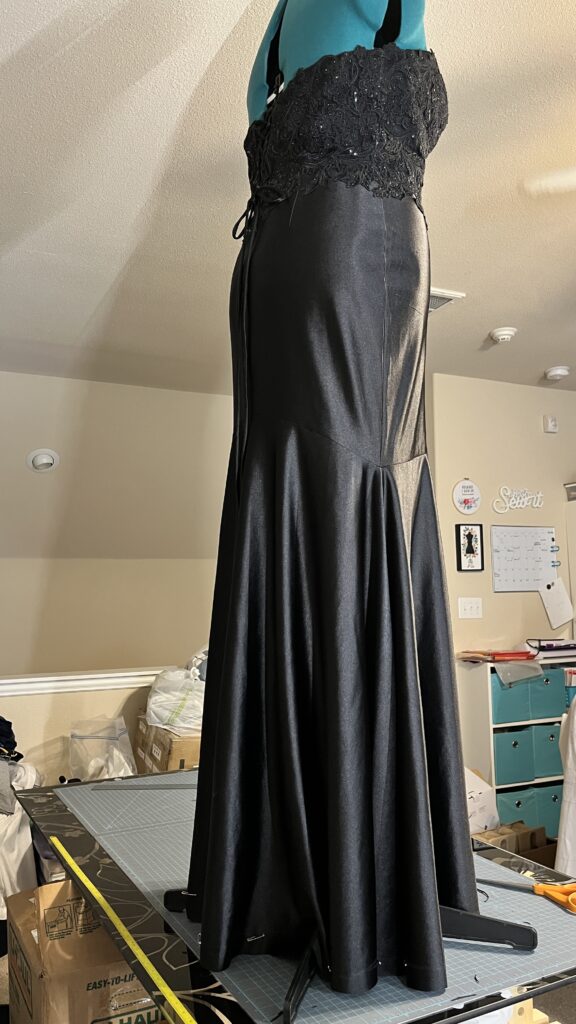

Once the bottom fold line of the hem is marked, the seam allowance is added and the dress is cut. When removing the train, I find cutting while the dress is on the body or dress form (in this case) is easiest and quickest. When cut along a flat and non-movable surface, this becomes quick work. It still needs some cleaning up, but it is visually straight. You can also use a laser level and cut along the projected line; a couple of tools and tricks of the trade.

Once cut, the dress hangs for 12-24 hours. This length depends on time allowed, but also can vary based on the materials of the garment. This is why I do not typically do dresses in less than 24 hours. If the fabric is heavy with embellishments such as beads or sequins, especially if it is a stretchy material, the cut is often completed in more than one cutting pass. The initial cut is made longer than anticipated. Then a waiting period. Then cut again if needed. If too much is cut initially, the dress may be too short as the weight is removed.

Commentary on Dress Sizing

I frequently ignore the fit on garments if I am being asked to do hems only. Unfortunately, it is not always my place to say that a garment does not fit, as badly as it hurts me inside my soul. It truly pains me. Even watching the stars walk down the red carpet causes me pain, knowing that they can afford a dress or suit that actually fits.

I find this the frustrating part of my job. I know the dress does not fit, but have to tactfully say something or simply say nothing at all. The population at large does not know how garments “should” fit. Unfortunately, many people who perform alterations are also unaware of garment-fitting techniques. It leaves those of us who are trained in fitting in a quandary of whether or not to say something to the client.

This customer had previously brought me a dress that I did not feel comfortable altering in the time frame needed, especially with my ongoing tendonitis problems. She got this dress a few days later. The dress is too small overall, but she is confident.

If you are looking for a dress, or any garment for that matter, fit the largest part of your body. It is far easier to take in a dress than it is to let it out. There used to be ample seams in formal wear where this was not the case, but those days are fading. These days, formal dresses have little to no seam allowance left in the seams, and these are much harder to “make larger.” With the absence of quality apparel fabric stores, color matching is difficult.

The finished hem! This fabric was good quality and heavy weight, but it did have a little stretch to it. The train is removed and the hemline sweeps the floor without being a tripping hazard. What matters at the end of the project is that the customer is excited about the results. Happy customers tend to be repeat customers.

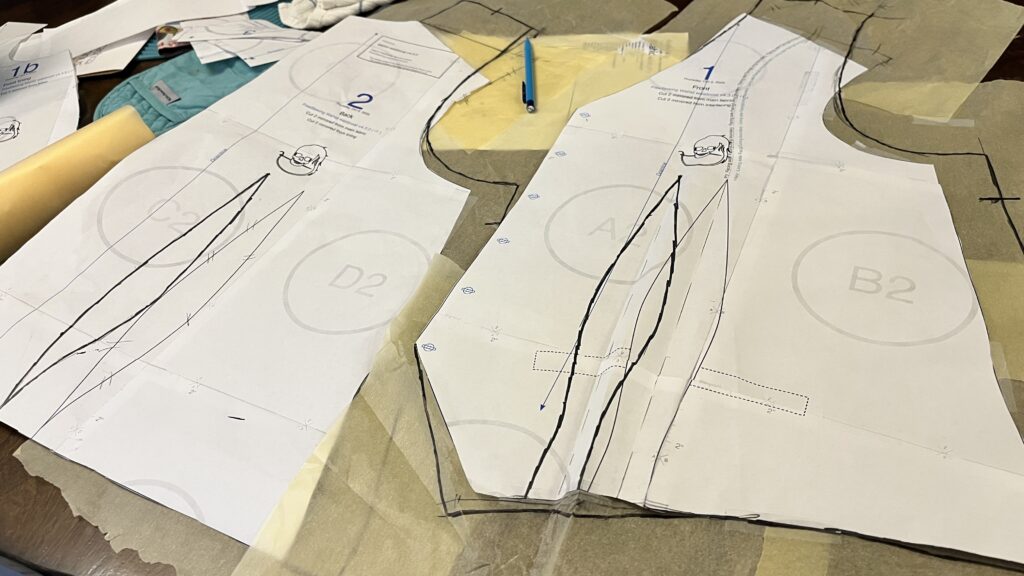

Pattern Fitting and Alterations

I do not get to do pattern making for customers very often. Most people do not utilize my custom sewing services, and fewer want to pay for custom pattern making. I am a little disappointed by this because custom patterns fit best.

Unfortunately, there are a lot of poorly designed sewing patterns out there on the market. Some claim to be “made to measure” when the results are far from that. In this case, poorly taken measurements result in ill-fitting garments.

This particular pattern was a “made to measure” pattern my niece had made through an automated website system. In theory, these automated patterning services do work, but they are not perfect. The results are only as good as the measurements input. This is also reflective of the measurements asked for.

In this case, the result was too small. She was asking for help to. Upon putting it up to her body, there were some critical flaws in the pattern. These came down to a poorly designed pattern overall.

This is why Stacey Sansom Designs offers free measurement services. Not everyone needs someone to hold their hand sewing, but it is difficult to measure yourself. Not sure what size you wear? Schedule your free measurement appointment today!

What can Stacey Sansom Designs do for you?

As you can see, Stacey Sansom Designs performs a variety of services each month. Some tasks are small, but make all the difference. Others are trickier and more time-consuming. If you have any questions about something you need (or want) done, contact me! I may ask you to send pictures to help me visualize your request, but start with the question.

Do you have an upcoming event? Do you need alterations or repairs completed? The calendar fills up quickly. Do not wait until the last minute! Schedule your quick and painless appointment today!